How Freudenberg’s Hydrogen Sealing Tech is Powering Safe, Leak-Free Fuel Cell Systems

April 15, 2025Solving Hydrogen’s Oldest Headache: Leaks

Hydrogen has a ton of potential — it’s lightweight, super abundant, and packs a serious energy punch. But it’s not all sunshine and rainbows. One of its biggest drawbacks? It’s a pain to contain. Because hydrogen molecules are so incredibly small and reactive, they tend to slip through even the tiniest gaps. We’re talking leaks in hydrogen fuel cell systems, storage cylinders, pipelines — basically everywhere. That’s where Freudenberg comes into the picture.

You might not hear about them every day, but Freudenberg — a German company with roots going all the way back to 1849 — is doing some critical behind-the-scenes work in building out the hydrogen infrastructure. Their specialty? Developing hydrogen sealing technology that can actually stand up to the tough demands of this challenging element. It may not be glamorous, but without solid seals, the hydrogen economy doesn’t stand a chance.

The Unsung Hero: Sealing Technology for Hydrogen Systems

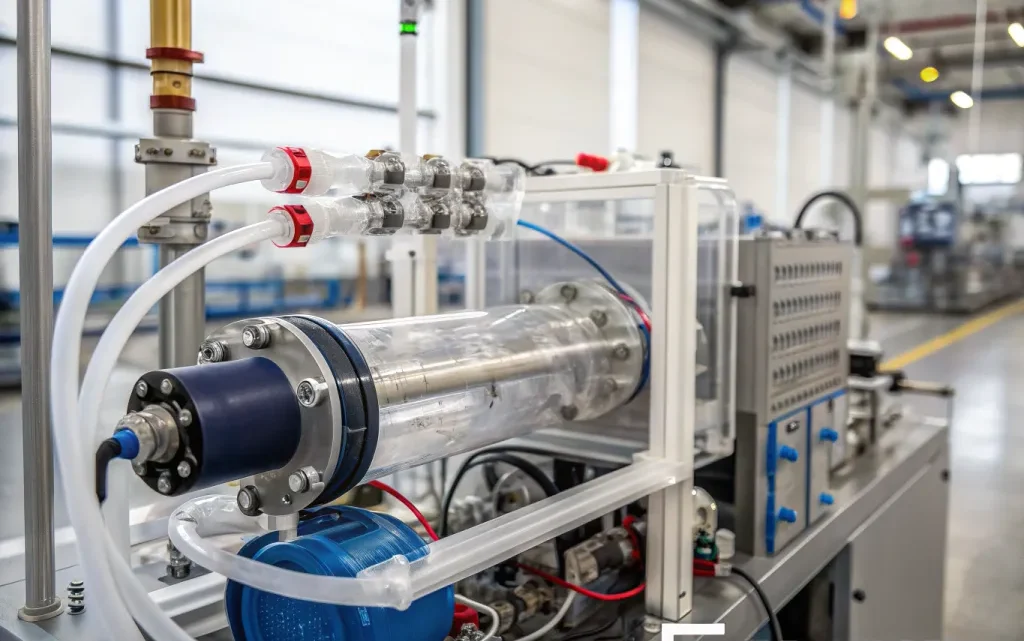

Let’s be real — seals don’t usually get the spotlight. But when it comes to hydrogen, they’re the quiet MVPs keeping everything running safely. Because hydrogen molecules are so tiny and slippery, standard industrial seals just don’t cut it. That’s why Freudenberg has developed a line of advanced, hydrogen-compatible sealing systems using high-performance elastomers and polymers. These materials are specially engineered to be flexible, durable, and resistant to pressure swings — exactly what hydrogen systems need.

From hydrogen fuel cells to storage tanks and pipelines, these seals are essential for keeping everything locked tight and leak-free. The materials science behind them helps ensure they hold up under punishing conditions — variable pressure, extreme temperatures, you name it — all without breaking down or letting gas escape.

Hydrogen Tech That’s Built to Last

Freudenberg’s hydrogen sealing technology isn’t just about slapping a part into place. It’s built with the big picture in mind — how the seal interacts with the complete system over time. We’re talking performance under constant pressure cycles, resistance to contamination, and how they age. These seals aren’t a quick fix — they’re designed for longevity and reliability, which is exactly what industries need as they switch to cleaner energy solutions.

By tackling one of hydrogen’s biggest technical challenges — safe containment — Freudenberg is doing more than just supplying components. They’re actively pushing the envelope on industrial decarbonization, helping make sustainable energy systems like zero-emission fuel cells practical for widespread use.

Strategic Focus on a Cleaner Future

Freudenberg’s move into the sustainable energy space isn’t just a business pivot — it’s a response to real global pressure for cleaner power. With the world urgently chasing net-zero emissions and ramping up investment in green hydrogen, there’s a growing need for specially engineered components that can thrive in these high-stakes environments.

They’re not doing it alone, either. Freudenberg is collaborating with companies like FuelCell Energy and XALT Energy to help push the limits in mobility, energy storage, and clean hydrogen production. With partnerships like these, they’re shaping up to be a key player in what’s coming next.

Zooming Out: Why Industry Stakeholders Should Care

If you’re an engineer, policymaker, or part of a company rolling out clean tech, seals might not be the first thing on your mind—until there’s a leak. Hydrogen isn’t just flammable—it’s expensive. Losing it through a bad seal can have serious safety and financial consequences.

Reliable hydrogen sealing technology translates to safer systems, better performance, and lower Total Cost of Ownership (TCO). And in an industry as competitive and innovation-driven as clean energy, every little edge counts. Sealing might be hidden in the background, but in this space, it’s fast becoming a decisive advantage.

The push for clean hydrogen and sustainable energy isn’t slowing down anytime soon. As more hydrogen hubs pop up and demand continues to grow, sealing solutions are moving from an afterthought to a core feature of system design. Freudenberg’s R&D investment is already syncing up with expanding market needs—with plans to stay ahead of the curve.

Expect to see hydrogen sealing technology become a major topic at industry conferences and in energy thought leadership. Because if hydrogen really is the fuel of the future, someone needs to make sure it stays where it’s supposed to — and Freudenberg is making sure it does just that.

With over 15 years of reporting hydrogen news, we are your premier source for the latest updates and insights in hydrogen and renewable energy.

With over 15 years of reporting hydrogen news, we are your premier source for the latest updates and insights in hydrogen and renewable energy.