Chinese Researchers Boost Efficiency of Photocatalytic Hydrogen Production with Double-Shelled Nanoboxes

April 19, 2025Breakthroughs in photocatalytic hydrogen production aren’t exactly new — but a fresh innovation out of China is catching serious attention across the clean energy space. And for good reason: this one could be a real game-changer when it comes to real-world applications.

A Closer Look: A Leap Forward with the S-Scheme

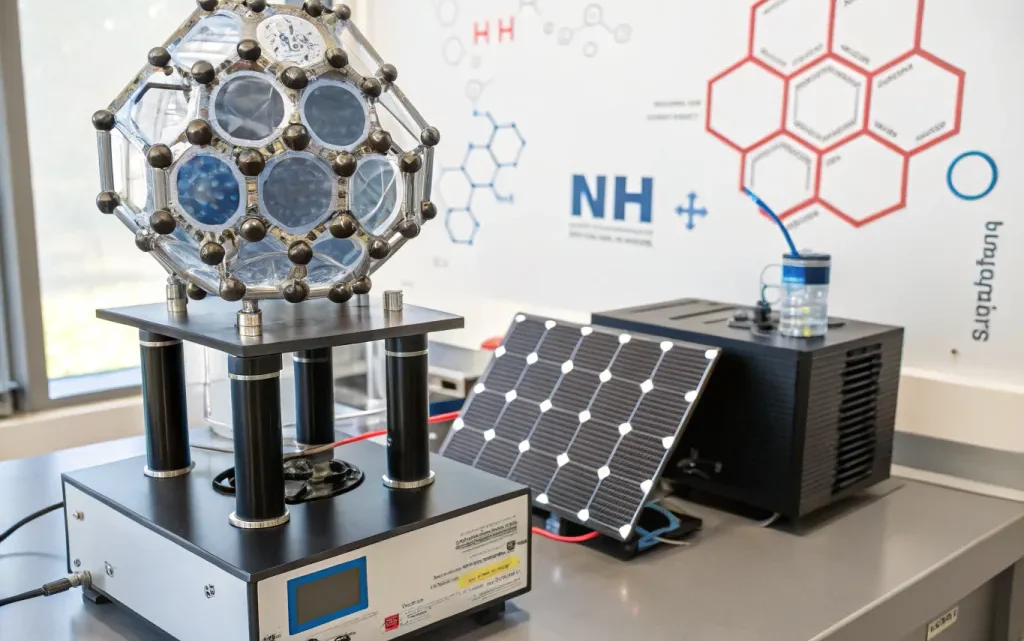

Researchers from the University of Science and Technology Beijing (USTB) and Nankai University have unveiled a new photocatalyst design that’s making waves. It’s called S-scheme CdS/Co₃S₄ double-shelled hollow nanoboxes — yeah, it’s a bit of a mouthful, but it packs a powerful punch when it comes to boosting solar-powered hydrogen production.

So, what makes this setup tick? It all comes down to better charge separation — a big deal in photocatalysis. The “S-scheme” design is inspired by the way plants use sunlight in photosynthesis, and it helps solve a long-standing issue where energetic electrons would normally fizzle out too quickly by recombining. This setup keeps that energy moving, which translates into more efficient hydrogen generation.

Why It Matters: Unlocking More Affordable Green Hydrogen

We’re in a race to decarbonize heavy industries and transportation, and a huge piece of that puzzle is finding efficient, affordable ways to generate hydrogen from renewable energy. That’s where this new photocatalyst really shines. It not only improves performance but also holds up better over time — and that could go a long way toward slashing the cost of green hydrogen.

“We’ve basically built a system where sunlight, charge transfer, and chemical reactions work together like a well-oiled machine,” said one of the researchers. And that’s largely thanks to the clever use of double-shelled hollow nanoboxes, which absorb more light, create more reaction space, and let chemicals move around easily inside their unique structure.

The Power Pair: CdS and Co₃S₄

This innovation brings together two well-known photocatalysts: cadmium sulfide (CdS) and cobalt sulfide (Co₃S₄). CdS is excellent at harvesting visible light but tends to break down quickly. Co₃S₄ helps stabilize the system and speeds up the all-important charge separation. Put them together using this new hollow, layered design, and you get the best of both worlds. Think of it like teaming up a powerhouse athlete with a smart strategist — it just works better together.

Backing It Up: Research Powerhouses Leading the Charge

It’s no surprise this kind of breakthrough is coming out of USTB and Nankai. USTB is already known for its work in metallurgy and clean energy research, while Nankai brings deep know-how in chemistry and nanotech. Their collaboration isn’t just about academic prestige — it’s part of a broader push by China to lead the way in green hydrogen solutions through serious, university-driven R&D.

This is also yet another example of how nanotechnology is stepping up to solve big-picture problems. These scientists aren’t just chasing lab results — they’re laying the groundwork for real, scalable solutions to cut emissions and make solar hydrogen production viable on a commercial level.

Bigger Potential: From the Lab to Heavy Industry

Looking beyond the lab bench, this tech has serious potential. It could directly influence the next generation of electrolyzers or be used in decentralized hydrogen production systems — especially where building massive centralized plants doesn’t make sense. Industries like steelmaking, freight, and shipping are all hunting for alternatives to fossil fuels, and a reliable, efficient photocatalyst could be just what they need to make the switch.

Sure, it’s early days — but the direction is clear. These little nanoboxes could be a key building block in the move toward solar-driven fuels.

What Comes Next?

Like any new tech, the next hurdle is scaling it up. Moving from small, lab-made samples to something that’s cost-effective and consistent at a larger scale isn’t easy. There are still challenges with production costs, how reproducible the process is, and whether the materials can hold up long term. But the researchers are optimistic. They’re already looking at real-world testing and ways to scale — a sign that we might not be waiting long to see this tech make the jump out of the lab.

As we look for cleaner ways to power industries, ships, trucks — even remote villages — it’s breakthroughs like these, built on smart materials and academic-industry collaboration, that might just tip the scales. One thing’s for sure: the world of efficient photocatalysis is heating up, and this could be a big step forward for clean, distributed hydrogen production.

With over 15 years of reporting hydrogen news, we are your premier source for the latest updates and insights in hydrogen and renewable energy.

With over 15 years of reporting hydrogen news, we are your premier source for the latest updates and insights in hydrogen and renewable energy.